RETHINKING IRON TO MAKE GREEN STEEL

T. Schneider / Shutterstock.com

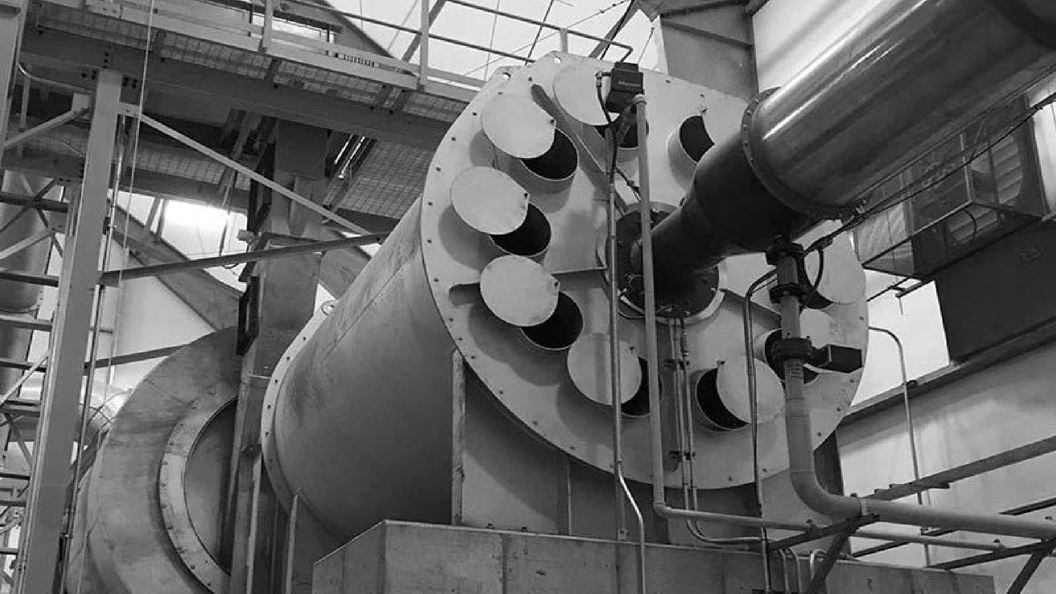

Steelmaking accounts for 7% of global greenhouse gas (GHG) emissions and 11% of global CO2 emissions (source: GEI), yet these emissions are among the hardest to abate. Most steel today is produced in coal or LNG fired blast furnaces, and the temperatures required (~1600 °C) don’t lend themselves to conventional (solar/wind) renewable solutions. Thus, the focus for producing green steel is on decarbonizing emissions from the steelmaking process itself, and miners have a role to play.

Green hydrogen process

According to a report from the Institute of Energy Economics and Financial Analysis (IEEFA) via RenewEconomy, switching from blast furnaces that consume coal to green hydrogen-based direct reduced iron (DRI) processes is widely considered a key step toward decarbonizing steelmaking. However, insufficient supply of suitable iron ore is a potential obstacle to global shift towards zero-emissions DRI.

The challenge is that DRI requires a higher grade of iron ore than conventional blast furnaces. DR-grade iron ore ideally has an iron (Fe) content of 67% or more, and such deposits are scarce. Per IEEFA, potential new DR-grade iron ore capacity by 2030 ranges from 40 million tonnes per annum (Mtpa) to an optimistic high of 100Mtpa. Yet, on current projections for a net-zero steel sector by 2050, the DR-grade ore supply may need to increase tenfold.

Options exist

Today, however, the largest miners remain mostly focused on continuing to supply blast furnaces with the lower-grade and highly profitable ores they currently produce. There are options though.

One option, says IEEFA, is a switch in iron ore mining focus from hematite towards magnetite. Magnetite ores tend to have a much lower Fe content but are often suitable for significant beneficiation, in part because magnetite is magnetic, enabling easier separation. These can often be beneficiated to DR-grade. Fortescue Metals Group (FMG), often on the cutting edge of the energy transition in the mining industry, is developing magnetite ore reserves at its Iron Bridge project, which could potentially add to DR-grade iron ore supply.

Still, more DRI may need to be made using lower-grade iron ore. This will necessitate melting the reduced iron before being charged into a basic oxygen furnace. This type of technology combination is being investigated by Rio Tinto in partnership with BlueScope Steel as well as ArcelorMittal. ThyssenKrupp is planning to begin replacing blast furnaces with DRI plants with integrated melting units from 2025.

Increased demand for green steel will likely be needed if steelmakers are to accelerate their low-emissions technology transition and iron ore miners are to increase focus on producing higher grade ore. But given the massive contributions of the steel sector to GHG emissions, such demand is inevitable. The challenge imposed by limited DR-grade iron ore supply on plans for a global scale-up of DRI production is significant, but with challenge comes opportunity.

Read more here.

DID YOU KNOW?

Green hydrogen is a necessary ingredient in the decarbonization of steelmaking. But for hydrogen to be called green, its production must be powered by renewable sources using a process, like electrolysis, that produces zero emissions. Producing large amounts of hydrogen in this way requires expensive electrolyzers that must operate 24/7 to be economical. Heat above 500 °C increases electrolyzer efficiency by up to 40% and reduces costs. Uniquely, 247Solar Plants™ produce combined heat and power (CHP), making them a low-cost 24/7 source of clean electricity and heat for producing abundant, economical green hydrogen. Read more here.

WESTERN COUNTRIES FORM CRITICAL MINERALS ALLIANCE

Reuters reports that Australia, Canada, France, Germany, Japan, the United Kingdom and the United States have launched the Sustainable Critical Minerals Alliance to produce and buy critical minerals from countries with stronger environmental and labor standards, a move that could reduce business with market leader China.

Announced at the COP15 talks on biodiversity in Montreal, the Alliance will develop standards for sustainable and inclusive mining and sourcing practices for elements like lithium, cobalt, nickel and rare earths.

Australian Mining further reports that through the Alliance, members will voluntarily work toward developing critical minerals practices that:

- Employ a nature-positive approach by encouraging industry practices or collaborating with industry on practices that prevent biodiversity loss, protect species at risk, support nature protection and minimise pollution, including driving toward net-positive benefits to the natural environment

- Support local and Indigenous communities by respecting the respective rights and interests of local and Indigenous communities through engagement; promoting safe working conditions and responsible labour standards, diverse and inclusive workforces, supporting safe living conditions; and including members of Indigenous and local communities in economic benefits from mining that affects their well-being

- Help fight climate change by reducing greenhouse gas emissions and working toward achieving net-zero emissions by no later than 2050, and promoting mining, processing and recycling processes that advance sustainability through ESG standards

- Restore ecosystems by adopting requirements for reclamation and remediation to close and return mine sites to their natural state where feasible and holding responsible parties accountable for environmental harm

- Build a circular economy by promoting material stewardship, including by-products and recovery from waste, keeping products in use longer as well as accelerating the reuse and recycling of critical minerals, which may reduce the number of new mines required to supply the minerals needed

- Foster ethical corporate practices through sustainability reporting to investors and the public and by implementing due diligence in mineral supply chains as laid down in relevant internationally accepted guidelines.

Canada’s Natural Resources Minister Jonathan Wilkinson said, “Unless China and Russia are willing to put in place … measures required to be able to legitimately say that they are supporting these kinds of standards then it would essentially mean … we will be buying alternatives as we can.”

Read more.

U.S. ANNOUNCES NUCLEAR FUSION BREAKTHROUGH

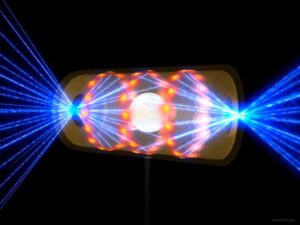

Lawrence Livermore Laboratory

“The creation of what amounts to a miniature star required 192 lasers, produced in a high-security federal government building the size of a football stadium. The lasers fired into a small chamber holding a pellet of hydrogen about half the size of a BB. As the beams fired, the atomic particles in the gas fused together and released more energy than the lasers had put in.”

So begins an article in the Washington Post about a remarkable achievement announced by U.S. Energy Secretary Jennifer Granholm on December 13th. For the first time ever, fusion researchers had produced a net-energy gain — a fusion reaction that puts out more energy than it consumes. The implications are enormous.

Fusion energy has long been considered the holy grail of limitless, zero-carbon power, and to be sure, this milestone is only a first step. It will likely be many more years before this technology can be used to build a power plant. “Probably decades,” said Kim Budil, director of the Lawrence Livermore laboratory where the demonstration took place. There are many technical hurdles to be overcome, but recall that the Wright Brothers’ first flight lasted 12 seconds and covered only 120 feet.

Read more here.

NEWS FROM 247SOLAR

247Solar granted Australia patent on core technology

The atmospheric-pressure solar receiver, thermal storage, flow-control devices and other related components behind our 247Solar Plants and HeatStorE™ long-duration thermal battery are now patent-protected in Australia, in addition to the United States and other key markets around the world. The Australian patent, issued on 13 October, joins more than 30 other patents that broadly & completely protect the entire field of “low-pressure-air solar power towers” in all major global markets.

The atmospheric-pressure solar receiver, thermal storage, flow-control devices and other related components behind our 247Solar Plants and HeatStorE™ long-duration thermal battery are now patent-protected in Australia, in addition to the United States and other key markets around the world. The Australian patent, issued on 13 October, joins more than 30 other patents that broadly & completely protect the entire field of “low-pressure-air solar power towers” in all major global markets.

FOLLOW & JOIN 247Solar

Contact: info@247solar.com